Common Myths About TIG Welding Torches Debunked: Your Essential Guide to Understanding TIG Welding Technology

Jul 06,2025

Common Myths About TIG Welding Torches Debunked

Table of Contents

- Myth 1: TIG Welding is Only for Professionals

- Myth 2: All TIG Torches are the Same

- Myth 3: TIG Welding is Too Complicated for Beginners

- Myth 4: You Can Only Use TIG Welding for Thin Materials

- Myth 5: TIG Welding Requires Special Gas

- Myth 6: Only AC Power Can Be Used for TIG Welding

- Myth 7: TIG Welding is Slow and Inefficient

- Myth 8: TIG Welding is Not Suitable for All Metals

- Frequently Asked Questions

- Conclusion

Myth 1: TIG Welding is Only for Professionals

TIG welding, or Tungsten Inert Gas welding, is often thought to be a technique reserved exclusively for professional welders. This misconception stems from the complexity associated with the process. However, **TIG welding can be accessible to hobbyists and DIY enthusiasts** as well. With advancements in technology and various user-friendly machines available in the market, anyone with a passion for welding can learn and master this skill. Numerous online resources, tutorials, and community forums offer guidance that can simplify the learning curve.

Myth 2: All TIG Torches are the Same

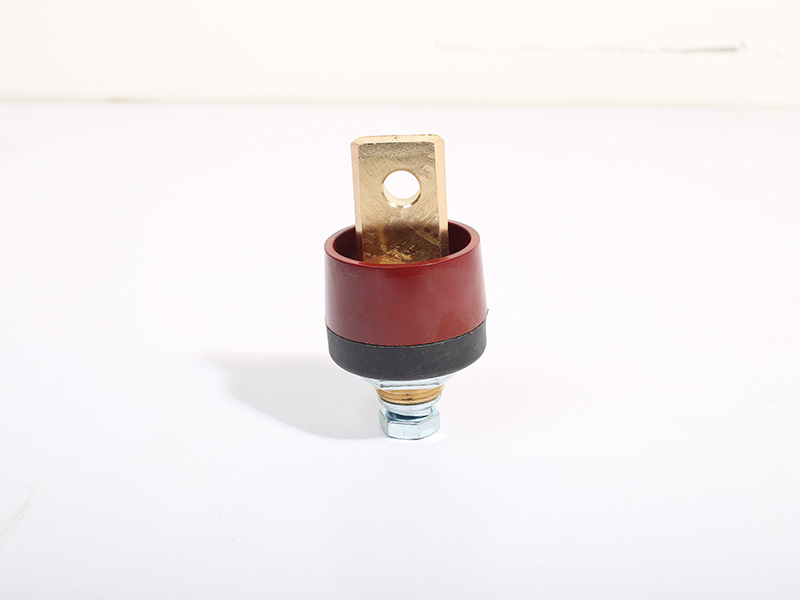

Another prevalent myth is that all TIG welding torches are interchangeable and function identically. In reality, **there are significant differences among TIG torches** regarding size, amperage capacity, and design. For instance, **water-cooled torches** are ideal for high-amperage applications, while **air-cooled torches** are more suitable for lighter tasks. Understanding the specifications and selecting the appropriate torch for your specific welding needs can lead to better results and increased efficiency.

Myth 3: TIG Welding is Too Complicated for Beginners

Many individuals shy away from TIG welding due to the belief that it is overly complex. While it is true that TIG welding involves various techniques, such as maintaining the proper arc length and using filler rods appropriately, **with practice, beginners can quickly become proficient**. Starting with simple projects and gradually progressing to more intricate tasks allows newcomers to build confidence and skill. Investing in a good welding machine and practicing regularly can demystify the process.

Myth 4: You Can Only Use TIG Welding for Thin Materials

This myth suggests that TIG welding is limited to thin materials like sheet metal. In fact, **TIG welding is versatile** and can be effectively used on thicker materials as well. While it is true that TIG welding excels in precision and controlling heat input, it is also capable of joining metals of varying thicknesses. Using the right settings, filler material, and techniques can yield excellent results, even on thicker workpieces.

Myth 5: TIG Welding Requires Special Gas

Many people believe that TIG welding requires unique gases for successful operation. This is **not entirely accurate**. While argon is the primary shielding gas used in TIG welding due to its inert properties, **other gases like helium can also be used** for specific applications. The choice of gas depends on factors such as material type and thickness. Understanding the characteristics of different gases can enhance your welding performance.

Myth 6: Only AC Power Can Be Used for TIG Welding

It is a common misconception that only alternating current (AC) is suitable for TIG welding. In reality, **both AC and direct current (DC) have their applications**. AC is typically used for welding aluminum and magnesium, while DC is preferred for ferrous metals. Recognizing when to use each type of current can improve efficiency and outcomes in your welding projects.

Myth 7: TIG Welding is Slow and Inefficient

Many believe that TIG welding is a slow process compared to other welding methods. While it is true that producing high-quality welds may take time, **the precision and control offered by TIG welding often result in fewer rework and higher-quality outputs**. Moreover, advancements in technology have led to the development of faster machines and improved techniques that enhance efficiency without compromising quality.

Myth 8: TIG Welding is Not Suitable for All Metals

Lastly, some individuals think that TIG welding cannot be used on all types of metals. In reality, **TIG welding is a highly versatile process** that can effectively join a wide variety of metals, including steel, aluminum, stainless steel, and even exotic materials like titanium. Knowing the correct settings, filler rod, and shielding gas for different metals can expand the versatility of TIG welding.

Frequently Asked Questions

1. What materials can I weld with a TIG welding torch?

You can weld various materials, including stainless steel, aluminum, copper, and titanium, among others. The choice of material will determine the settings and filler rods you should use.

2. How do I maintain my TIG welding torch?

Regular maintenance is crucial for optimal performance. Keep the torch clean, check for damages, and replace the tungsten electrode as needed. Ensure that the gas lines are free from leaks and that the connections are secure.

3. What type of shielding gas should I use for TIG welding?

Argon is the most commonly used shielding gas for TIG welding. However, for specific metals like aluminum, a mixture of argon and helium may provide enhanced performance.

4. Can I use TIG welding for thick materials?

Yes, TIG welding can be used on thick materials by adjusting the amperage settings and using appropriate filler rods. It is crucial to ensure adequate heat penetration for effective fusion.

5. Is TIG welding safe?

Like all welding processes, TIG welding involves hazards. However, with proper safety gear—such as gloves, masks, and protective clothing—along with following safety protocols, you can minimize risks.

Conclusion

In summary, understanding the realities of TIG welding torches is essential for anyone interested in this versatile welding technique. By debunking common myths, we can empower both professionals and novices to explore the vast potential of TIG welding. Whether you're aiming for precision in thin materials or tackling thicker sections, the right knowledge and equipment can significantly enhance your welding outcomes. Embracing the truth behind these myths opens doors to new possibilities and greater success in your welding projects.

Add

Xing village, lvgongbao town, renqiu city, hebei province, china