language

The Essential Guide to Welding: Techniques, Equipment, and Best Practices

Jun 11,2025

Welding is a crucial process in the industrial equipment and components sector, especially when it comes to the fabrication and assembly of materials. It involves joining two or more pieces of metal through the application of heat, pressure, or both. Understanding the different welding techniques and equipment available can significantly impact the quality and efficiency of your projects.

There ar

Welding is a crucial process in the industrial equipment and components sector, especially when it comes to the fabrication and assembly of materials. It involves joining two or more pieces of metal through the application of heat, pressure, or both. Understanding the different welding techniques and equipment available can significantly impact the quality and efficiency of your projects.

There are several welding techniques that professionals frequently use, each with unique benefits and applications. One of the most common is MIG (Metal Inert Gas) welding, which is known for its speed and versatility. This method uses a continuous wire feed as an electrode and an inert gas to protect the weld from contamination. It is particularly effective for thin materials and is widely used in automotive and manufacturing industries.

TIG (Tungsten Inert Gas) welding is another popular technique, especially for projects requiring high precision. This process uses a non-consumable tungsten electrode to produce the weld, which allows for a cleaner and more controlled application. TIG welding is ideal for thin materials and can be used on a variety of metals, including aluminum and stainless steel.

Stick welding, or SMAW (Shielded Metal Arc Welding), is a more traditional method that is often used in construction and repair work. It is known for its ability to work in outdoor conditions and on rusty or dirty materials. The process involves melting a coated electrode to create the weld, making it a versatile choice for various applications.

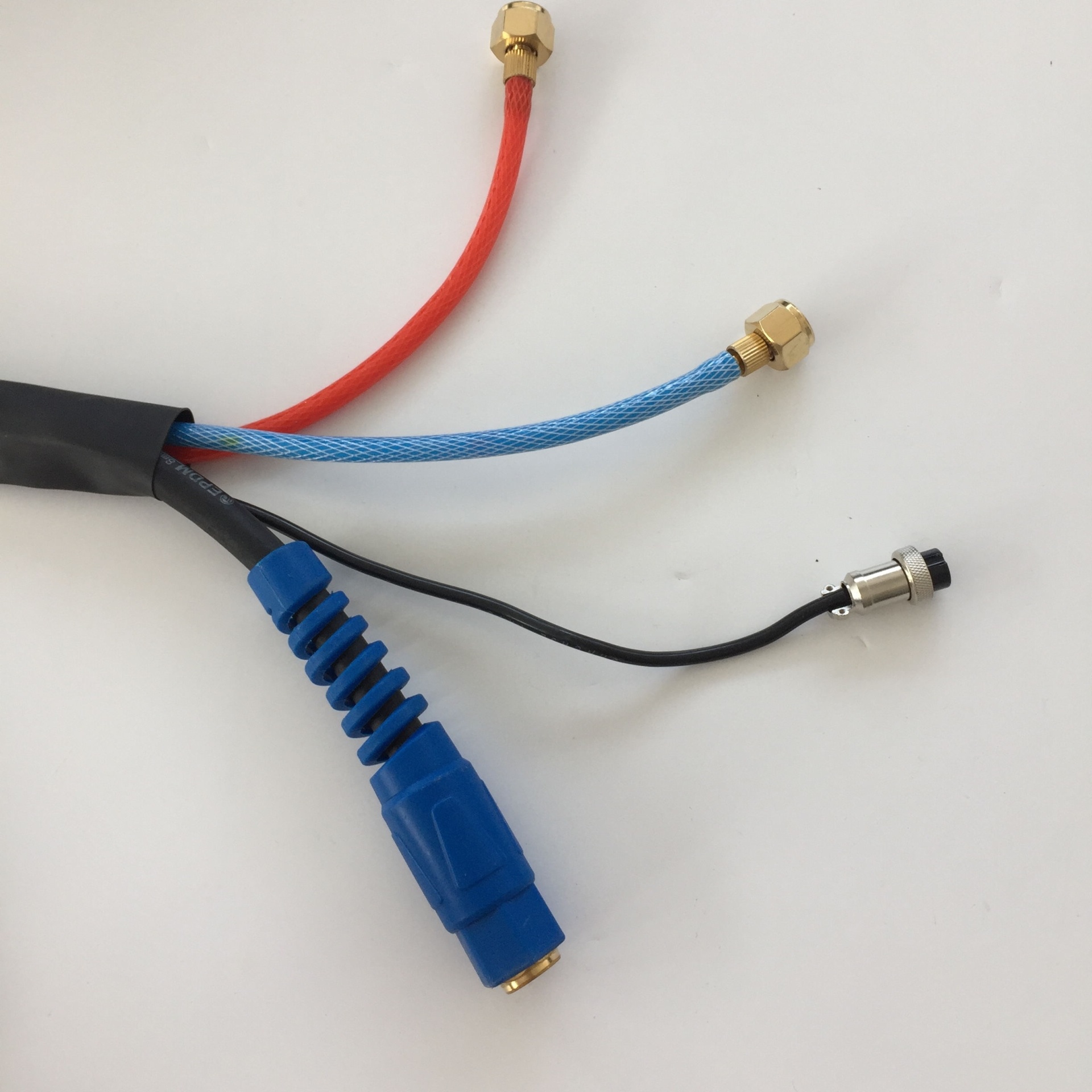

Investing in the right welding equipment is equally important. Essential tools include welding machines, protective gear, and accessories such as welding helmets, gloves, and aprons. Proper protective equipment is critical, as it shields the welder from harmful sparks, UV radiation, and heat. Moreover, selecting a machine that suits your specific needs—whether it's for heavy-duty industrial work or lighter projects—can enhance your welding performance significantly.

It's also important to adhere to best practices in welding to ensure safety and quality. Always ensure your workspace is well-ventilated and free from flammable materials. Regularly inspect your equipment for wear and tear, and maintain a clean work area to prevent accidents. Furthermore, continuous education and training in welding techniques can help professionals stay updated on the latest practices and technologies in the field.

In summary, understanding the nuances of welding techniques, choosing the appropriate equipment, and following safety protocols are essential for success in the industrial equipment and components sector. By investing time in learning and practicing these fundamentals, you can enhance your welding capabilities and contribute to the efficiency and quality of your projects.

There are several welding techniques that professionals frequently use, each with unique benefits and applications. One of the most common is MIG (Metal Inert Gas) welding, which is known for its speed and versatility. This method uses a continuous wire feed as an electrode and an inert gas to protect the weld from contamination. It is particularly effective for thin materials and is widely used in automotive and manufacturing industries.

TIG (Tungsten Inert Gas) welding is another popular technique, especially for projects requiring high precision. This process uses a non-consumable tungsten electrode to produce the weld, which allows for a cleaner and more controlled application. TIG welding is ideal for thin materials and can be used on a variety of metals, including aluminum and stainless steel.

Stick welding, or SMAW (Shielded Metal Arc Welding), is a more traditional method that is often used in construction and repair work. It is known for its ability to work in outdoor conditions and on rusty or dirty materials. The process involves melting a coated electrode to create the weld, making it a versatile choice for various applications.

Investing in the right welding equipment is equally important. Essential tools include welding machines, protective gear, and accessories such as welding helmets, gloves, and aprons. Proper protective equipment is critical, as it shields the welder from harmful sparks, UV radiation, and heat. Moreover, selecting a machine that suits your specific needs—whether it's for heavy-duty industrial work or lighter projects—can enhance your welding performance significantly.

It's also important to adhere to best practices in welding to ensure safety and quality. Always ensure your workspace is well-ventilated and free from flammable materials. Regularly inspect your equipment for wear and tear, and maintain a clean work area to prevent accidents. Furthermore, continuous education and training in welding techniques can help professionals stay updated on the latest practices and technologies in the field.

In summary, understanding the nuances of welding techniques, choosing the appropriate equipment, and following safety protocols are essential for success in the industrial equipment and components sector. By investing time in learning and practicing these fundamentals, you can enhance your welding capabilities and contribute to the efficiency and quality of your projects.

PREVIOUS:

Add

Xing village, lvgongbao town, renqiu city, hebei province, china