language

Essential Insights into Welding Guns: Understanding Their Importance and Functionality

Jul 21,2025

Welding guns are indispensable tools in the electrical and welding industry, playing a crucial role in various welding processes. These devices are designed to deliver heat and pressure to join two or more metal pieces together, making them essential for both professional welders and hobbyists alike. Understanding the types and functions of welding guns can significantly improve the quality of you

Welding guns are indispensable tools in the electrical and welding industry, playing a crucial role in various welding processes. These devices are designed to deliver heat and pressure to join two or more metal pieces together, making them essential for both professional welders and hobbyists alike. Understanding the types and functions of welding guns can significantly improve the quality of your work and the safety of your operations.

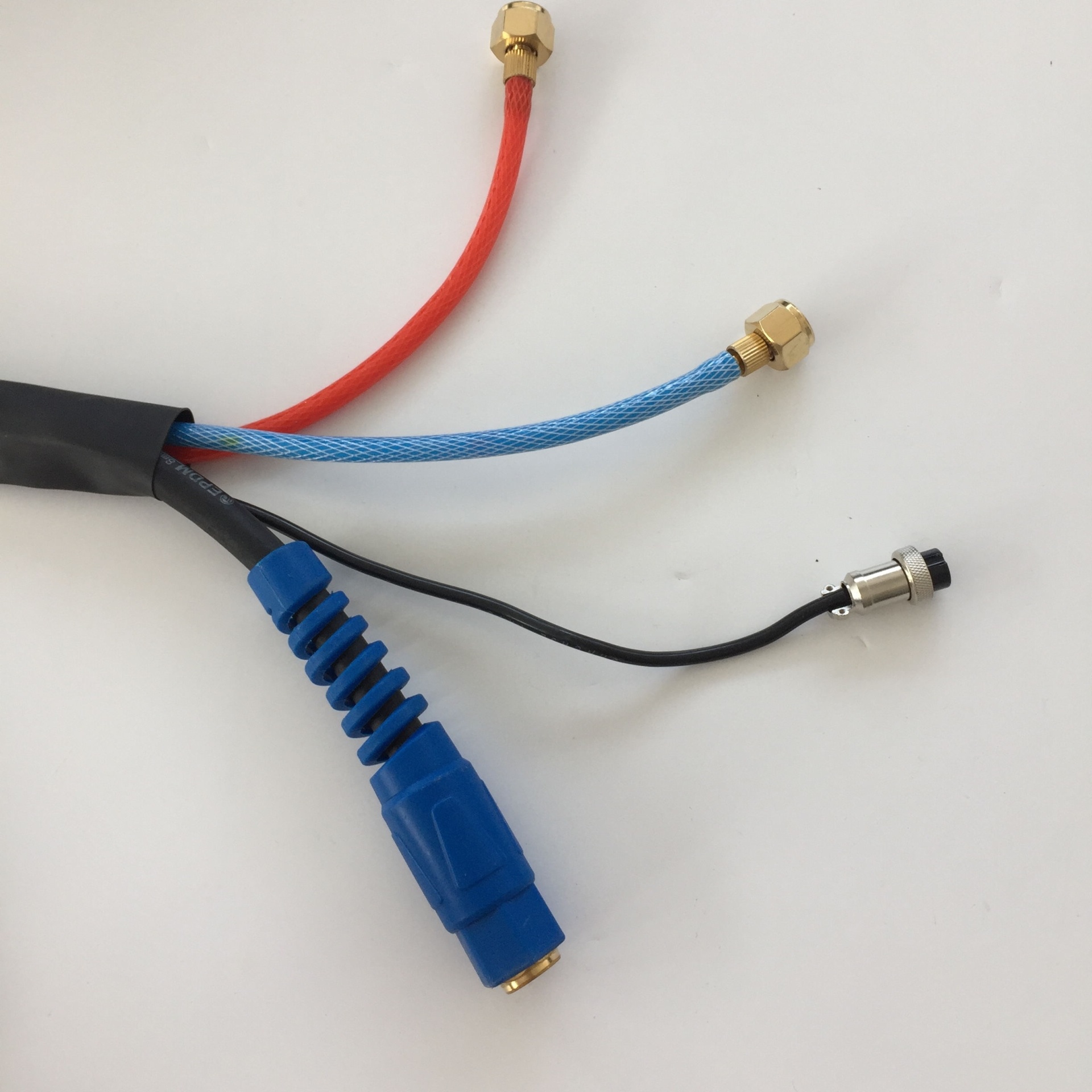

There are several types of welding guns available, each tailored for specific welding techniques. The most common types include MIG (Metal Inert Gas) welding guns and TIG (Tungsten Inert Gas) welding guns. MIG welding guns are popular for their ease of use and versatility, making them ideal for a wide range of applications, from light fabrication to heavy-duty industrial work. On the other hand, TIG welding guns are favored for their precision, allowing for finer control over the weld, which is especially beneficial for intricate projects or when working with thin materials.

When selecting a welding gun, consider factors such as the material thickness you will be working with, the type of welding process you intend to use, and the ergonomic design for prolonged use. A comfortable grip and lightweight design can significantly reduce fatigue during extended welding sessions. Additionally, ensure the welding gun has an appropriate duty cycle, indicating how long it can operate before needing a break to cool down.

Proper maintenance of welding guns is essential for ensuring their longevity and performance. Regularly inspect the nozzle for wear and replace it as needed, as a worn nozzle can lead to subpar welds. Keep the welding gun clean and free from debris, which can interfere with heat transfer and overall efficiency. Moreover, using the correct filler materials and settings for your specific project will enhance the quality of your welds and reduce the chances of defects.

Safety should always be a top priority when working with welding guns. Use appropriate personal protective equipment (PPE), such as gloves, masks, and protective clothing, to shield yourself from sparks, UV radiation, and harmful fumes. Additionally, ensure your workspace is well-ventilated to minimize exposure to harmful gases.

In conclusion, understanding the functionality, types, and maintenance of welding guns is critical for anyone involved in the welding and electrical industries. By choosing the right welding gun for your specific needs, maintaining it properly, and prioritizing safety, you can achieve better results in your welding projects and improve overall productivity. Whether you are fabricating metal structures or performing repairs, a good welding gun is your best ally in achieving high-quality work.

There are several types of welding guns available, each tailored for specific welding techniques. The most common types include MIG (Metal Inert Gas) welding guns and TIG (Tungsten Inert Gas) welding guns. MIG welding guns are popular for their ease of use and versatility, making them ideal for a wide range of applications, from light fabrication to heavy-duty industrial work. On the other hand, TIG welding guns are favored for their precision, allowing for finer control over the weld, which is especially beneficial for intricate projects or when working with thin materials.

When selecting a welding gun, consider factors such as the material thickness you will be working with, the type of welding process you intend to use, and the ergonomic design for prolonged use. A comfortable grip and lightweight design can significantly reduce fatigue during extended welding sessions. Additionally, ensure the welding gun has an appropriate duty cycle, indicating how long it can operate before needing a break to cool down.

Proper maintenance of welding guns is essential for ensuring their longevity and performance. Regularly inspect the nozzle for wear and replace it as needed, as a worn nozzle can lead to subpar welds. Keep the welding gun clean and free from debris, which can interfere with heat transfer and overall efficiency. Moreover, using the correct filler materials and settings for your specific project will enhance the quality of your welds and reduce the chances of defects.

Safety should always be a top priority when working with welding guns. Use appropriate personal protective equipment (PPE), such as gloves, masks, and protective clothing, to shield yourself from sparks, UV radiation, and harmful fumes. Additionally, ensure your workspace is well-ventilated to minimize exposure to harmful gases.

In conclusion, understanding the functionality, types, and maintenance of welding guns is critical for anyone involved in the welding and electrical industries. By choosing the right welding gun for your specific needs, maintaining it properly, and prioritizing safety, you can achieve better results in your welding projects and improve overall productivity. Whether you are fabricating metal structures or performing repairs, a good welding gun is your best ally in achieving high-quality work.

PREVIOUS:

Add

Xing village, lvgongbao town, renqiu city, hebei province, china