language

Understanding Welding Guns: Essential Tools for Effective Welding

Apr 12,2025

Welding guns are specialized tools designed to deliver focused heat to metals, allowing for effective joining through processes like MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding. These guns serve as the point of contact where the welding arc is generated, making them a vital component in various welding applications.

At the core of any welding gun is its design, which typically consi

Welding guns are specialized tools designed to deliver focused heat to metals, allowing for effective joining through processes like MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding. These guns serve as the point of contact where the welding arc is generated, making them a vital component in various welding applications.

At the core of any welding gun is its design, which typically consists of several key elements: the trigger mechanism, the nozzle, and the electrode holder. The trigger is essential for controlling the flow of electrical current and the feed of the welding wire, allowing for precise operations. The nozzle, often made from durable materials to withstand high temperatures, protects the welding area from contaminants and helps direct the shielding gas around the weld pool. Lastly, the electrode holder is where the welding wire is fed through, providing a continuous feed of material to ensure a strong bond between the metals being welded.

There are different types of welding guns, each tailored for specific applications. For instance, a MIG welding gun is designed for using a continuous wire feed, making it ideal for projects requiring speed and efficiency. Conversely, a TIG welding gun, which relies on a non-consumable tungsten electrode, is often favored for its ability to produce high-quality, precision welds, especially in thin materials.

The operation of a welding gun is not merely about heating the metals; it also involves the careful selection of parameters such as voltage, wire feed speed, and travel speed. These factors directly influence the quality of the weld and the overall success of the project. Understanding how to adjust these settings is crucial for professionals looking to achieve optimal results.

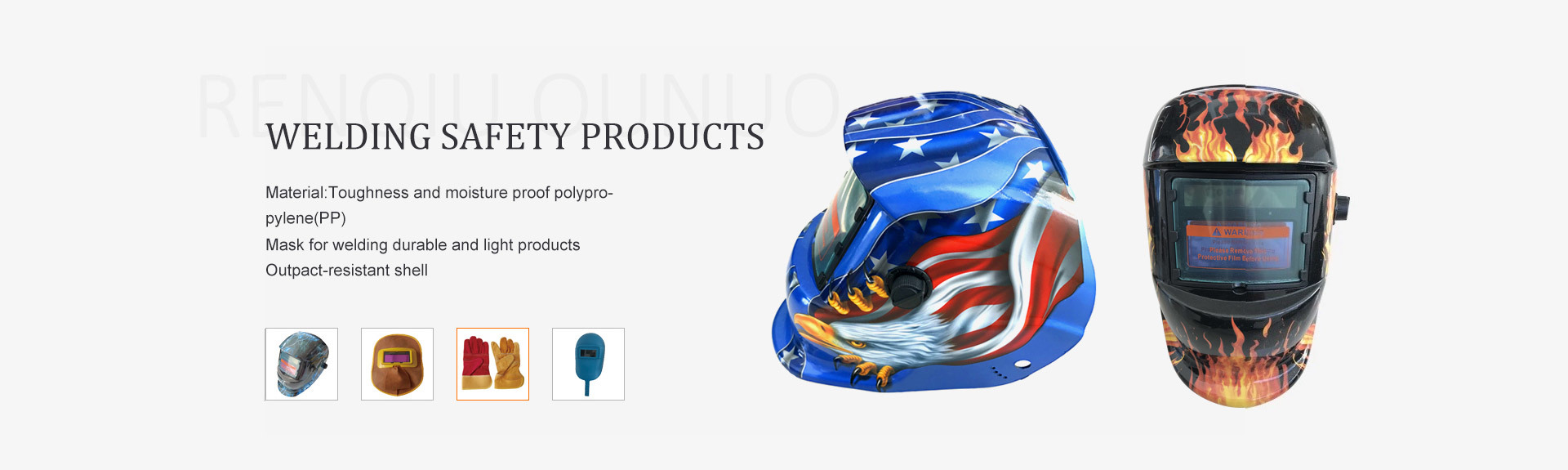

Safety is an important consideration when using welding guns. Proper protective gear, including helmets and gloves, should always be worn to safeguard against hazardous sparks and intense UV radiation emitted during the welding process. Additionally, maintaining the welding gun in good condition through regular inspections and cleaning is vital to ensure its longevity and efficiency.

In conclusion, welding guns are indispensable tools in the electrical and welding industries, providing the necessary means to join metals effectively. By understanding their components, types, and operational principles, professionals can enhance their welding techniques and achieve superior results. Whether you are engaged in heavy industrial fabrication or intricate artistic projects, mastering the use of welding guns will significantly elevate your craftsmanship.

At the core of any welding gun is its design, which typically consists of several key elements: the trigger mechanism, the nozzle, and the electrode holder. The trigger is essential for controlling the flow of electrical current and the feed of the welding wire, allowing for precise operations. The nozzle, often made from durable materials to withstand high temperatures, protects the welding area from contaminants and helps direct the shielding gas around the weld pool. Lastly, the electrode holder is where the welding wire is fed through, providing a continuous feed of material to ensure a strong bond between the metals being welded.

There are different types of welding guns, each tailored for specific applications. For instance, a MIG welding gun is designed for using a continuous wire feed, making it ideal for projects requiring speed and efficiency. Conversely, a TIG welding gun, which relies on a non-consumable tungsten electrode, is often favored for its ability to produce high-quality, precision welds, especially in thin materials.

The operation of a welding gun is not merely about heating the metals; it also involves the careful selection of parameters such as voltage, wire feed speed, and travel speed. These factors directly influence the quality of the weld and the overall success of the project. Understanding how to adjust these settings is crucial for professionals looking to achieve optimal results.

Safety is an important consideration when using welding guns. Proper protective gear, including helmets and gloves, should always be worn to safeguard against hazardous sparks and intense UV radiation emitted during the welding process. Additionally, maintaining the welding gun in good condition through regular inspections and cleaning is vital to ensure its longevity and efficiency.

In conclusion, welding guns are indispensable tools in the electrical and welding industries, providing the necessary means to join metals effectively. By understanding their components, types, and operational principles, professionals can enhance their welding techniques and achieve superior results. Whether you are engaged in heavy industrial fabrication or intricate artistic projects, mastering the use of welding guns will significantly elevate your craftsmanship.

Add

Xing village, lvgongbao town, renqiu city, hebei province, china