language

The Best Welding Helmets for Professional Welders: A Comprehensive Guide

Apr 27,2025

The Best Welding Helmets for Professional Welders: A Comprehensive Guide

When it comes to welding, safety is paramount. One of the most critical pieces of protective gear that every professional welder should invest in is a high-quality welding helmet. This article serves as your ultimate guide to understanding the best welding helmets available today, featuring essential features, top brands, and

The Best Welding Helmets for Professional Welders: A Comprehensive Guide

When it comes to welding, safety is paramount. One of the most critical pieces of protective gear that every professional welder should invest in is a high-quality welding helmet. This article serves as your ultimate guide to understanding the best welding helmets available today, featuring essential features, top brands, and expert recommendations. We aim to equip you with the necessary knowledge to make an informed decision, ensuring your safety and efficiency on the job.

Table of Contents

- Introduction to Welding Helmets

- The Importance of a Quality Welding Helmet

- Key Features to Look for in Welding Helmets

- Top Brands of Welding Helmets

- Best Welding Helmets for Professionals

- Maintaining Your Welding Helmet

- Frequently Asked Questions

- Conclusion

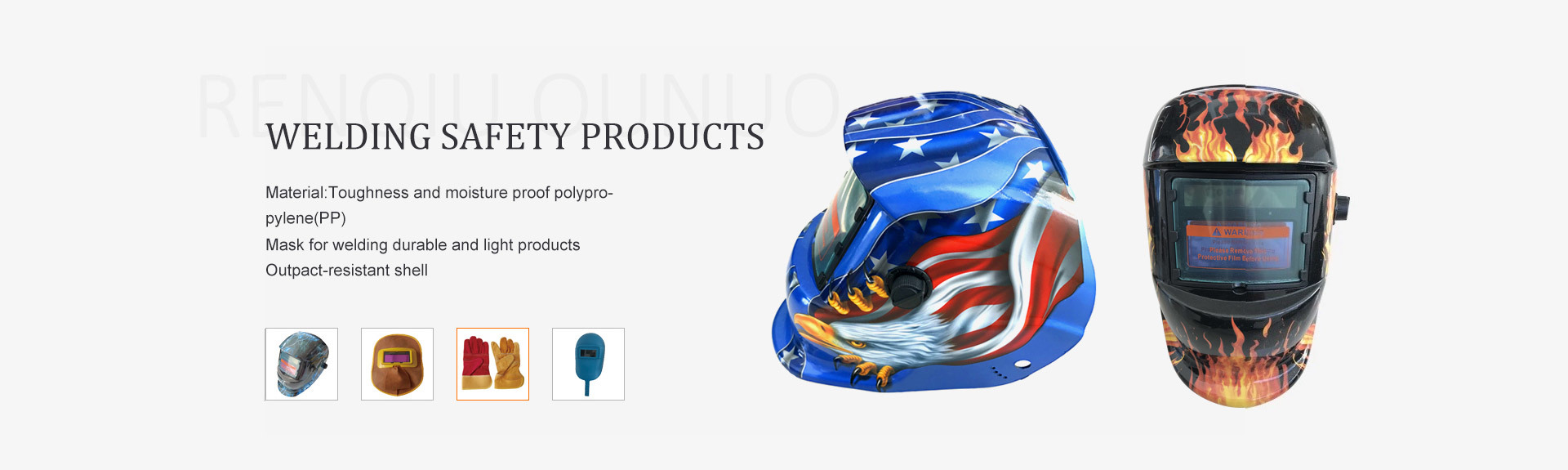

Introduction to Welding Helmets

Welding helmets are an essential part of a welder's personal protective equipment (PPE). They not only protect the eyes and face from harmful light, sparks, and heat but also enhance visibility during the welding process. Understanding what to look for in a welding helmet can significantly impact your safety and performance.

The Importance of a Quality Welding Helmet

Investing in a quality welding helmet is crucial for several reasons:

Protection from UV and IR Rays

Welding emits intense ultraviolet (UV) and infrared (IR) radiation, which can cause severe eye damage and skin burns. A high-quality welding helmet features filters that block these harmful rays. A good helmet will effectively protect welders from these dangers, ensuring they can perform their work safely.

Preventing Eye Injuries and Burns

Eye injuries are a common hazard in welding. Arc flashes can occur unexpectedly, leading to arc eye, a painful condition resulting from exposure to bright light. Additionally, sparks and molten metal can cause burns to the face and neck. A well-designed welding helmet minimizes these risks, allowing you to focus on your work without fear of injury.

Key Features to Look for in Welding Helmets

When selecting a welding helmet, there are several key features to consider:

Auto-Darkening Lenses

Auto-darkening lenses are one of the most sought-after features in modern welding helmets. These lenses automatically adjust their shade based on the brightness of the welding arc, providing optimal protection without the need for manual adjustments. This feature enhances convenience and efficiency, allowing welders to maintain focus on their work.

Lens Shade Options

Welding helmets come with various lens shade options, typically ranging from shade 9 to shade 13. The appropriate shade depends on the type of welding being performed. For instance, MIG welding often requires a lighter shade, while TIG welding may necessitate a darker lens. It's essential to choose a helmet with adjustable shade options to cater to different welding applications.

Weight and Comfort

Welders often work for extended periods, making the weight and comfort of a helmet crucial. A lightweight helmet can reduce fatigue, while padded headbands and adjustable settings enhance comfort during long welding sessions. Look for helmets that offer both comfort and a secure fit.

Field of View

A wide field of view is essential for effective welding. Helmets with larger viewing areas allow welders to see their work more clearly, improving accuracy and reducing the chance of mistakes. Choosing a helmet with an adequate field of view can significantly enhance the quality of your work.

Top Brands of Welding Helmets

Several brands are renowned for producing high-quality welding helmets. Some of the top brands include:

- **Lincoln Electric**: Known for their durable and reliable welding equipment, Lincoln Electric offers a range of helmets suitable for professionals.

- **Miller Electric**: Another industry leader, Miller Electric helmets are designed with advanced features for improved safety and performance.

- **ESAB**: ESAB helmets are favored for their innovative designs and high-quality materials, providing excellent protection and comfort.

- **3M**: 3M welding helmets stand out for their comfort and superior lens technology, making them ideal for long hours of use.

- **Jackson Safety**: Jackson Safety helmets are popular among welders for their affordability and effectiveness, catering to a broad range of welding applications.

Best Welding Helmets for Professionals

Here, we will highlight some of the best welding helmets currently available for professional welders, focusing on features, benefits, and user feedback.

Model 1: Lincoln Electric K3034-4 VIKING 3350

The Lincoln Electric K3034-4 VIKING 3350 is a top choice among professionals. It boasts a large viewing area of 3.74" x 3.34" and features an auto-darkening lens with a shade range of 1/1/1/2. The helmet is designed for comfort, with a lightweight structure and padded headgear. Users praise its clarity and responsiveness, making it suitable for various welding applications.

Model 2: Miller Electric Digital Infinity

The Miller Electric Digital Infinity helmet is another excellent option. It features a large viewing area and an auto-darkening lens with a shade range of 8 to 13. The helmet includes multiple memory settings, allowing users to customize their preferences for different welding processes. Its comfortable fit and robust design make it a favorite among professional welders.

Model 3: ESAB Sentinel A50

The ESAB Sentinel A50 helmet is known for its innovative design and advanced features. It offers a 1/1/1/1 optical clarity rating and a large viewing area. The auto-darkening lens adjusts quickly to changing light conditions, ensuring consistent visibility. Users appreciate its lightweight design and excellent comfort, which are essential for long hours of welding.

Maintaining Your Welding Helmet

Proper maintenance of your welding helmet is essential to ensure its longevity and effectiveness. Here are a few tips for maintaining your helmet:

1. **Regular Cleaning**: Clean the exterior and interior of the helmet regularly to remove dust, grime, and spatter. Use a soft cloth and mild soap to avoid scratches on the lens.

2. **Check the Lens**: Inspect the lens for any cracks or damage. Replace the lens if you notice any imperfections that could obstruct your view.

3. **Store Properly**: When not in use, store your helmet in a cool, dry place to prevent damage from environmental factors.

4. **Replace Batteries**: If your helmet features electronic components, ensure to replace the batteries as needed for optimal performance.

Frequently Asked Questions

1. What is the average lifespan of a welding helmet?

The average lifespan of a welding helmet varies based on usage and maintenance but typically ranges from 3 to 5 years.

2. How do I choose the right shade for my welding helmet?

Choosing the right shade depends on the type of welding you perform. Generally, shades 9-13 are suitable for arc welding, while lower shades (8-10) may be more appropriate for MIG welding.

3. Are expensive welding helmets worth the investment?

Yes, investing in a high-quality welding helmet often leads to better protection, comfort, and performance, making it worthwhile for professional use.

4. Can I use a welding helmet for different types of welding?

Most modern welding helmets are versatile and suitable for various welding processes, but it's essential to check the specifications before use.

5. What features should I look for in a beginner welding helmet?

Beginners should look for a helmet with auto-darkening features, a comfortable fit, and adjustable shade options to accommodate different welding techniques.

Conclusion

Choosing the right welding helmet is crucial for ensuring safety and enhancing performance in welding operations. By understanding the importance of quality helmets, recognizing key features to look for, and exploring top brands and models, professional welders can make informed decisions that protect them while working. Investing in a high-quality welding helmet pays off in safety, comfort, and efficiency, making it an essential component of any welder's gear. Remember to maintain your helmet properly to extend its lifespan and effectiveness, ensuring you remain protected on the job for years to come.

PREVIOUS:

Add

Xing village, lvgongbao town, renqiu city, hebei province, china