language

Your Ultimate Guide to Welding Torches: Types and Uses

Apr 17,2025

Your Ultimate Guide to Welding Torches: Types and Uses

Welding is an essential process in various industries, from automotive manufacturing to construction. A critical component of this process is the **welding torch**, which plays a vital role in joining materials. In this comprehensive guide, we will explore the different types of welding torches, their specific applications, and tips for select

Your Ultimate Guide to Welding Torches: Types and Uses

Welding is an essential process in various industries, from automotive manufacturing to construction. A critical component of this process is the **welding torch**, which plays a vital role in joining materials. In this comprehensive guide, we will explore the different types of welding torches, their specific applications, and tips for selecting the right tool for your welding projects. By the end of this article, you will be well-equipped to make informed choices about welding torches.

Table of Contents

- 1. Introduction to Welding Torches

- 2. Types of Welding Torches

- 3. Key Components of Welding Torches

- 4. How to Choose the Right Welding Torch

- 5. Safety Tips for Using Welding Torches

- 6. Common Mistakes to Avoid

- 7. Frequently Asked Questions

- 8. Conclusion

1. Introduction to Welding Torches

Welding torches are specialized tools designed to produce a controlled flame or arc to melt and join materials, primarily metals. Understanding the different types of torches and their applications is crucial for achieving high-quality welds. This guide will delve into the various welding torches available in the market, helping you identify the best fit for your specific needs.

2. Types of Welding Torches

Welding torches come in several types, each suited for specific welding processes and materials. Let's explore the main types of welding torches:

2.1 Oxy-Fuel Torches

Oxy-fuel torches, also known as gas welding torches, use a mixture of oxygen and a fuel gas, typically acetylene, to produce a flame. This type of torch is versatile and ideal for various applications, including cutting, brazing, and welding.

**Key Features:**

- **Adjustable Flame:** The flame can be adjusted for different welding tasks.

- **Portable:** These torches are easy to move, making them suitable for onsite jobs.

- **Cost-Effective:** Oxy-fuel setups are often more affordable than other welding methods.

**Common Uses:**

- Metal cutting

- Repair work

- Soldering

2.2 TIG Torches

TIG (Tungsten Inert Gas) torches utilize a non-consumable tungsten electrode to produce a stable arc. An inert gas, typically argon, protects the weld area from contamination. This method is known for its precision and is widely used in industries requiring high-quality welds.

**Key Features:**

- **High Control:** Offers excellent control over the welding process.

- **Clean Welds:** Produces clean and strong welds with minimal spatter.

- **Versatile:** Suitable for a wide range of materials, including stainless steel and aluminum.

**Common Uses:**

- Aerospace applications

- Automotive industry

- Artistic metalwork

2.3 MIG Torches

MIG (Metal Inert Gas) torches are designed for a semi-automatic welding process, where a continuous wire feed acts as the electrode. The process is fast and efficient, making it popular among manufacturers and DIY enthusiasts alike.

**Key Features:**

- **Speed:** Offers high welding speed, ideal for larger projects.

- **Ease of Use:** Simple setup and operation make it beginner-friendly.

- **Versatility:** Can be used on various materials, including mild steel and aluminum.

**Common Uses:**

- Fabrication shops

- Automotive repairs

- Home projects

2.4 Plasma Cutting Torches

Plasma cutting torches utilize a high-velocity jet of ionized gas (plasma) to cut through metals. This torch type is perfect for cutting thick materials quickly and efficiently.

**Key Features:**

- **Precision Cutting:** Allows for intricate cuts with fine detail.

- **Speed:** Cuts through materials faster than traditional methods.

- **Minimal Heat Affected Zone:** Reduces warping and damage to surrounding metal.

**Common Uses:**

- Industrial cutting

- Metal fabrication

- Art projects

3. Key Components of Welding Torches

Understanding the components of a welding torch is essential for both operation and maintenance. Each torch type has unique components, but some common parts include:

3.1 Torch Body

The torch body houses the other components and is usually made of durable materials to withstand high temperatures.

3.2 Handles

Handles are designed for comfort and control during operation. They may include ergonomic designs to reduce fatigue.

3.3 Nozzle

The nozzle directs the flow of gas or plasma. Different nozzles can be used for varying applications to control the flame shape and size or plasma arc.

3.4 Electrode

In TIG torches, the electrode is composed of tungsten, which does not melt during the welding process. Proper electrode selection is vital for successful welding.

3.5 Gas Supply

The gas supply is crucial for providing the necessary gas for the welding process. In oxy-fuel torches, this includes both oxygen and a fuel gas.

4. How to Choose the Right Welding Torch

Choosing the right welding torch depends on several factors, including your specific application, the materials you will be working with, and your skill level. Here are some tips to help you make the right decision:

4.1 Assess Your Needs

Consider the types of projects you'll undertake. If you're working on automotive repairs, a MIG torch might be best, whereas precision work may require a TIG torch.

4.2 Understand Material Compatibility

Different torches work better with specific materials. For example, aluminum often requires TIG welding, while MIG is excellent for mild steel.

4.3 Evaluate Your Skill Level

If you are a beginner, consider starting with a MIG torch due to its ease of use. As you gain experience, you can expand to other types.

4.4 Budget Considerations

Determine your budget for welding equipment. Oxy-fuel setups are generally more affordable compared to advanced TIG or plasma cutting torches.

5. Safety Tips for Using Welding Torches

Safety is paramount when using welding torches. Follow these essential safety tips to protect yourself and others:

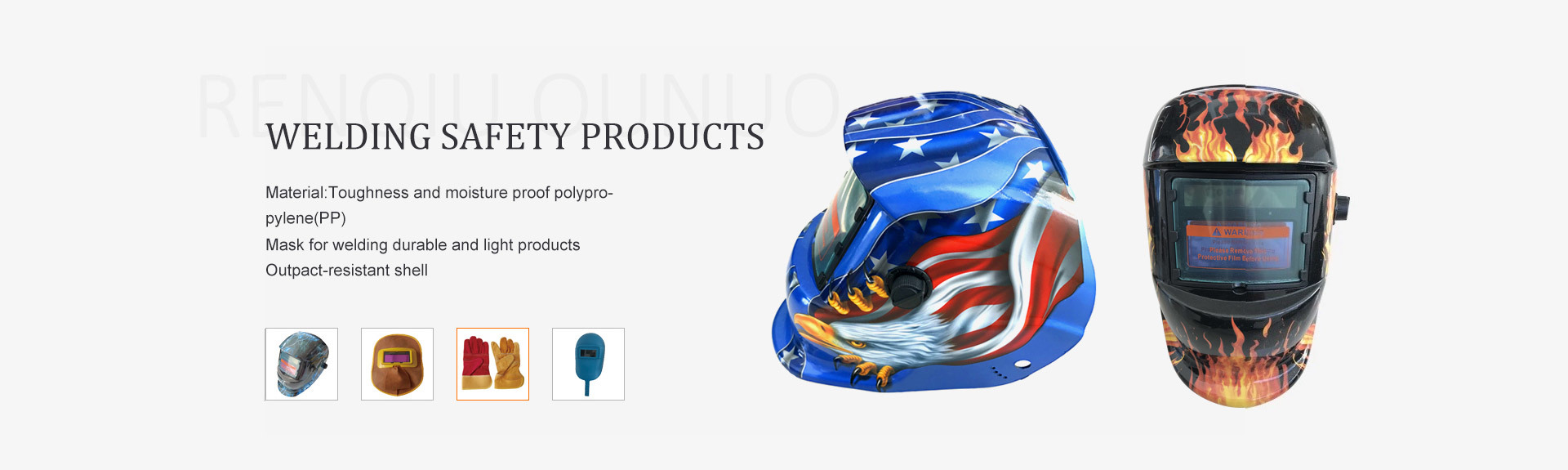

5.1 Wear Protective Gear

Always wear appropriate personal protective equipment (PPE), including welding helmets, gloves, and flame-resistant clothing.

5.2 Ensure Proper Ventilation

Welding produces harmful fumes. Work in well-ventilated areas to minimize exposure.

5.3 Keep a Fire Extinguisher Handy

Have a fire extinguisher accessible in your workspace. Welding can ignite flammable materials, so preparedness is crucial.

5.4 Follow Manufacturer Instructions

Read and understand the user manual for your specific torch model. This ensures you operate the equipment safely and effectively.

6. Common Mistakes to Avoid

Even seasoned welders can make mistakes when using welding torches. Here are some common pitfalls to avoid:

6.1 Incorrect Settings

Always adjust your torch settings according to the material and thickness you are working with. Incorrect settings may lead to weak welds or excessive burn-through.

6.2 Ignoring Maintenance

Regular maintenance is essential for extending the life of your torch. Neglecting to clean or replace worn components can affect performance.

6.3 Poor Technique

Practicing proper welding technique is crucial. Inconsistent movement or improper angle can compromise weld quality.

6.4 Not Checking Gas Levels

Before starting a project, always check your gas levels to avoid interruptions during the welding process.

7. Frequently Asked Questions

7.1 What is the best welding torch for beginners?

For beginners, a **MIG torch** is often recommended due to its ease of use and versatility.

7.2 Can I use a TIG torch for aluminum welding?

Yes, TIG torches are excellent for welding aluminum and other non-ferrous metals due to the precision they offer.

7.3 How often should I replace my welding torch components?

Component replacement depends on usage. Regularly inspect your torch and replace parts like nozzles and electrodes when they show signs of wear.

7.4 What safety gear do I need for welding?

Essential safety gear includes a welding helmet, gloves, fire-resistant clothing, and safety glasses.

7.5 How do I prevent weld contamination?

Ensure that the material is clean and free from oil, dirt, and rust. Additionally, use inert gas to shield the weld area from atmospheric contamination.

8. Conclusion

Welding torches are indispensable tools in the welding process, each designed for specific applications and materials. By understanding the different types of welding torches, their components, and how to choose the right one, you can significantly enhance your welding capabilities. Always prioritize safety and maintenance to ensure quality results. With the insights provided in this guide, we hope you feel empowered to tackle your welding projects with confidence and skill.

Add

Xing village, lvgongbao town, renqiu city, hebei province, china